The 7-Point Construction Quality Control Checklist (2025)

Why a Quality Control Checklist is Non-Negotiable

This construction quality control checklist empowers you to oversee your building project effectively. From foundation to finish, learn how to verify critical aspects, ensuring your dream home is built to the highest standards. This list covers essential checks, including materials testing, dimensional accuracy, workmanship, building envelope integrity, MEP (Mechanical, Electrical, and Plumbing) systems, safety and code compliance, and documentation. Using a construction quality control checklist helps avoid costly rectifications and ensures a smooth, successful project. It’s essential for achieving a beautiful, functional, and durable home that meets your exact specifications.

1. Materials Testing and Inspection

A crucial component of any robust construction quality control checklist is materials testing and inspection. This systematic verification process ensures that all construction materials delivered to your Australian building site meet the required specifications and quality standards, safeguarding the integrity and longevity of your project, whether it's a custom luxury residence, a modern extension, or a bespoke renovation. This involves a range of tests, from checking concrete strength and verifying steel properties to evaluating soil compaction and inspecting prefabricated components before installation. This process is especially vital for discerning homeowners investing in high-end projects where quality and durability are paramount.

Materials testing and inspection involves several key features, including scheduled testing intervals based on material type and construction phase. Thorough documentation of material certificates and test results is essential. For critical components, third-party laboratory testing offers an unbiased assessment. Maintaining a clear chain of custody for samples ensures the reliability of test results. Additionally, non-destructive testing options are available for materials already installed. These features contribute to a comprehensive quality control process.

Implementing a robust materials testing regime offers numerous advantages. It prevents the use of substandard materials that could compromise structural integrity, a particularly important consideration for multi-story extensions. It provides documented evidence of compliance with Australian building codes and specifications, giving you peace of mind. By identifying issues before materials are installed, this process reduces costly rework and delays. Furthermore, the data gathered provides valuable insights for future maintenance and renovation decisions, contributing to the long-term value of your property.

While essential, materials testing does have some drawbacks. It can potentially delay construction if test results are not received promptly. It adds cost to the project budget, although this is a small price to pay for the long-term benefits. The process requires coordination with testing laboratories and specialists. Finally, while rigorous, testing may not catch every single defect, especially in very large material batches.

Examples of successful implementations of materials testing programs highlight its importance. Skanska's meticulous material testing protocol on the New Karolinska Hospital in Sweden involved over 10,000 test samples, showcasing the scale required for large projects. Hochtief's concrete testing program on the Burj Khalifa included automated monitoring of curing conditions, demonstrating the use of technology for enhanced quality control. Similarly, Turner Construction’s use of QR code tracking for material verification on healthcare projects illustrates the potential of digital tools in streamlining this process. Learn more about Materials Testing and Inspection

For your project, consider these actionable tips: Develop a comprehensive material testing schedule at the project's inception. Establish clear rejection/acceptance criteria for each material based on Australian standards. Utilize digital tools to track sample collection and test results efficiently. Don't hesitate to perform additional testing if a visual inspection raises any concerns. Maintaining a library of approved material samples can be a valuable reference for future comparisons.

Organizations such as ASTM International, the Construction Specifications Institute (CSI), the International Code Council (ICC), and the American Concrete Institute (ACI) have popularized and standardized many of these crucial testing procedures. By including materials testing and inspection in your construction quality control checklist, you're making a proactive investment in the quality, durability, and value of your property.

2. Dimensional Quality Control

Dimensional quality control is a critical component of any construction quality control checklist, especially for complex projects like custom luxury residences, modern extensions, or bespoke renovations. It involves the precise verification of spatial accuracy, alignment, elevations, and tolerances throughout the construction process. This means ensuring that everything from foundations and structural elements to mechanical systems and finishes are installed exactly as designed and within the acceptable tolerances specified. This rigorous process helps prevent costly errors, ensures a seamless fit of prefabricated components, and ultimately delivers a higher-quality final product.

For discerning homeowners investing in high-end projects, dimensional quality control provides the peace of mind that their vision is being realized with precision. It employs advanced surveying equipment like total stations and 3D scanners to establish benchmarks and reference points, enabling progressive dimensional verification at key construction milestones. This ensures that any deviations are identified and corrected early, preventing cascading errors that can compound throughout the construction phases and become significantly more expensive to rectify later. Specific tolerance specifications for different building elements, such as walls, windows, and doors, are adhered to, resulting in a precise fit and finish. As-built documentation, which compares the actual dimensions to the designed dimensions, is meticulously maintained, offering complete transparency and accountability.

Examples of Successful Implementation: Large-scale projects, like Laing O'Rourke's use of digital twin technology on the Francis Crick Institute and Bechtel's implementation of reality capture for the Crossrail project in London, demonstrate the effectiveness of dimensional quality control. These technologies are also increasingly being adopted for residential construction, with companies like Mortenson Construction using BIM verification for dimensional control in healthcare facilities, a practice transferable to high-end residential projects.

Pros:

- Ensures proper fit of prefabricated components, crucial for modern construction methods.

- Prevents cascading errors that compound through construction phases, saving time and money.

- Reduces clashes between different building systems (e.g., structural, mechanical, electrical).

- Facilitates precise installation of high-end equipment and fixtures in luxury residences.

- Improves overall aesthetic quality and functionality, delivering a premium finish.

Cons:

- Can be a time-intensive process requiring skilled personnel.

- Equipment calibration is critical and can introduce errors if not managed correctly.

- Challenging in renovation projects with existing dimensional irregularities, demanding careful planning and adaptation.

- Can create conflicts between different trade tolerances, requiring proactive coordination.

Tips for Effective Dimensional Quality Control:

- Establish a robust control network with redundant checkpoints throughout the site.

- Conduct dimensional checks before critical stages like concrete placement or wall closure.

- Utilize digital tools like BIM software to compare as-built conditions with design models in real-time.

- Meticulously document all dimensional deviations and obtain necessary approvals for any variances.

- Implement independent verification of critical dimensions by different team members for increased accuracy.

Why this matters in a Construction Quality Control Checklist: Dimensional quality control deserves its place on the checklist because it directly impacts the structural integrity, functionality, and aesthetics of the final build. For affluent homeowners and those seeking high-quality construction, this level of precision is essential for achieving the desired outcome and avoiding costly rework. This is particularly important in the AU region with its strict building codes and emphasis on quality construction. The adoption of BIM protocols, Autodesk Construction Cloud, and Trimble Connect further emphasizes the importance of digital tools in ensuring precise dimensional control, which is particularly relevant for technology-oriented homeowners seeking smart, energy-efficient homes.

3. Workmanship Standards Verification

Workmanship Standards Verification is a critical component of any construction quality control checklist, especially for discerning homeowners investing in high-end projects. It involves the meticulous evaluation of construction techniques, craftsmanship, and installation quality against established industry benchmarks, project specifications, and your personal vision for excellence. This encompasses everything from the precision of joint treatments and the effectiveness of fastening methods to the overall aesthetic appeal of the finished product across all trades, ensuring a seamless and superior result. This process ensures that the final product not only meets but exceeds expectations for luxury and longevity.

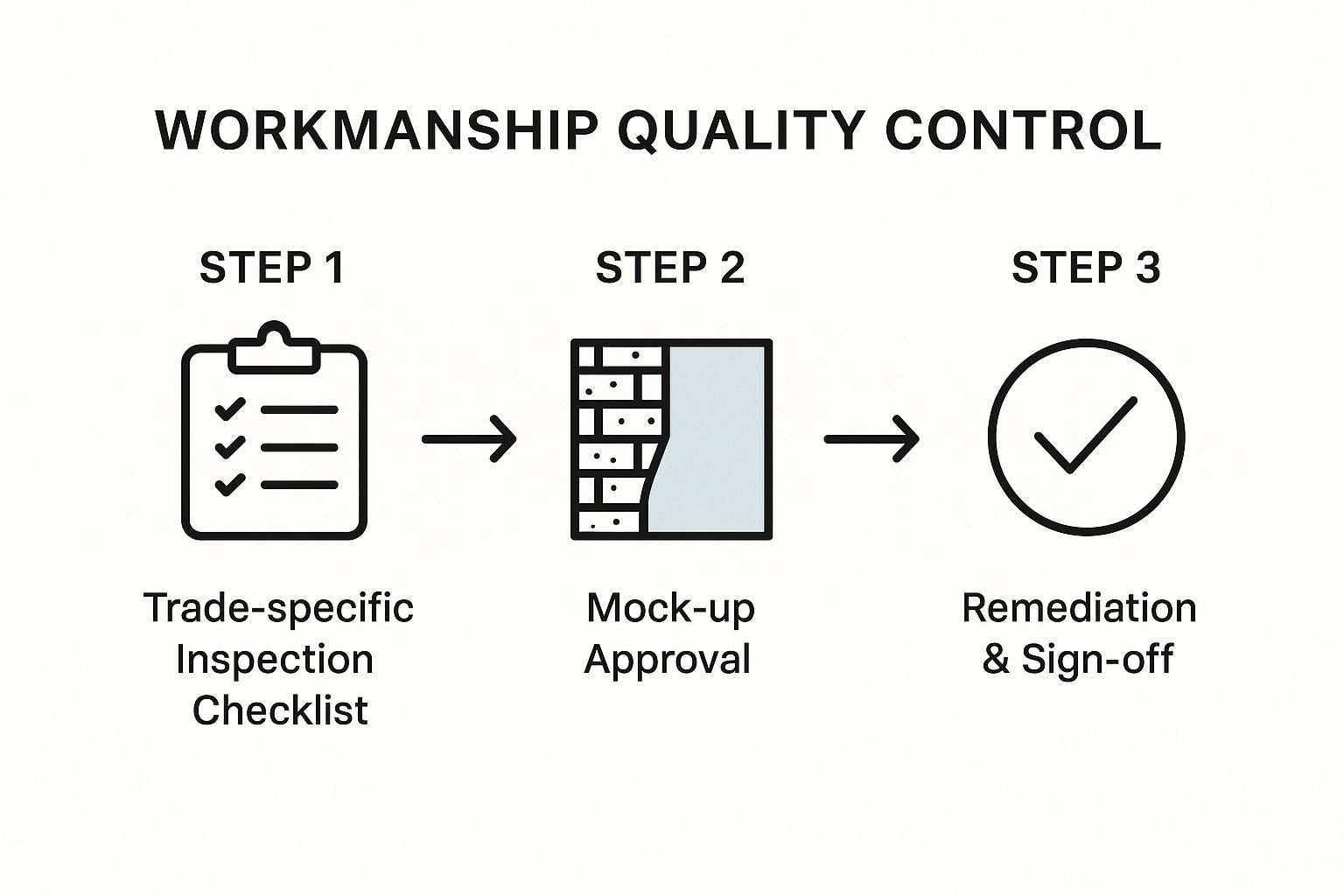

The infographic illustrates the cyclical process of workmanship standards verification. It starts with establishing clear standards and then moves through the stages of inspection, identification of defects, implementation of corrective actions, and verification of the implemented corrections. This loop continues until the desired level of quality is achieved, highlighting the iterative nature of quality control and the importance of continuous improvement. The final step, documentation and reporting, ensures a comprehensive record of the entire process for future reference and accountability.

For homeowners in the AU region undertaking substantial projects like custom luxury residences, modern extensions, bespoke renovations, or smart, energy-efficient homes, this meticulous approach is indispensable. Imagine the frustration of discovering flaws in your dream home after completion. Workmanship Standards Verification mitigates this risk. By establishing clear expectations from the outset and implementing rigorous checks throughout the construction process, you safeguard your investment and ensure a final product that reflects your vision.

This element of the construction quality control checklist deserves its place because it directly addresses the tangible quality of the build. Specific features like trade-specific inspection checklists, photographic documentation, mock-up approvals, progressive inspections, and defined remediation procedures ensure every detail is scrutinized and rectified if necessary. For instance, before tiling begins, a mock-up section can be created to demonstrate the chosen pattern, grout colour, and finish, allowing you to approve the aesthetic before full-scale installation.

The benefits are numerous. It establishes clear expectations for quality across all trades, from carpentry and electrical work to plumbing and painting. This significantly reduces the likelihood of callbacks and warranty issues, saving you time and money in the long run. By upholding high standards of workmanship, you also enhance building performance and longevity, contributing to the overall value and durability of your home. Furthermore, the visual records created during the verification process serve as valuable documentation for future maintenance and renovations.

While the advantages are compelling, it's crucial to be aware of the potential drawbacks. Subjective evaluations can sometimes lead to disputes, highlighting the need for clear communication and agreed-upon standards from the outset. The process also requires inspectors with trade-specific expertise to accurately assess workmanship quality. It's important to note that standards can vary between regions and contractors, so it's essential to establish clear expectations early on. Finally, consistent documentation and enforcement can be time-consuming, although the long-term benefits outweigh this investment.

Examples of successful implementation of rigorous workmanship standards include Suffolk Construction's quality control program on the Encore Boston Harbor resort, Multiplex's use of interactive tablets for real-time quality checks on the Perth Children's Hospital, and Lendlease's comprehensive quality verification system for the MoMA expansion in New York. These examples demonstrate the effectiveness of robust workmanship standards verification in large-scale projects and provide inspiration for similar diligence in high-end residential construction.

Actionable tips for homeowners:

- Create photographic references for acceptable workmanship: This provides a visual benchmark for all parties involved.

- Conduct regular toolbox talks on quality expectations: Reinforce the importance of quality with all tradespeople.

- Implement a "first-work" inspection for each new trade or crew: This allows for early identification and correction of any deviations from the established standards.

- Develop clear remediation protocols for common defects: This ensures consistent and timely rectification of any issues.

- Use consistent scoring systems for workmanship evaluation: This promotes objectivity and transparency.

Organisations like the Construction Management Association of America (CMAA), AECOM's quality management system, various guilds and trade associations, and ISO 9001 certification requirements have all popularized and contributed to the development of robust workmanship standards. By incorporating these best practices into your construction project, you ensure a result that embodies quality, precision, and lasting value.

4. Building Envelope Quality Control

Building envelope quality control is a critical component of any construction quality control checklist, especially for discerning homeowners in Australia investing in high-end custom builds, modern extensions, or bespoke renovations. This specialized inspection process focuses on the exterior enclosure systems—your home's first line of defense against the elements. It involves meticulous verification of everything that separates your interior from the exterior environment: water/air barriers, insulation, flashing, windows and doors (fenestration), roofing, and cladding systems. This comprehensive approach ensures weathertightness, optimal thermal performance, and long-term durability.

This process is essential for several reasons. It employs a layer-by-layer inspection approach before each layer is concealed, preventing hidden defects. Advanced techniques like water testing (spray rack and flood testing), thermal imaging to pinpoint insulation gaps, and air infiltration testing are used to identify and address potential issues before they escalate. Specific attention is given to detail verification at transitions and penetrations—often the most vulnerable areas for leaks and energy loss.

For technology-oriented homeowners seeking smart, energy-efficient homes, or those planning second or ground floor extensions, building envelope quality control is paramount. A well-sealed and insulated envelope translates directly to lower energy bills, improved indoor comfort, and a reduced carbon footprint. This meticulous approach prevents costly water damage, mould growth, and protects your interior finishes, ensuring your investment stands the test of time.

Pros:

- Prevents costly water damage and mould issues.

- Improves energy efficiency and occupant comfort.

- Reduces maintenance costs and extends building lifespan.

- Protects interior finishes and building contents.

- Addresses one of the highest risk areas for building failure.

Cons:

- Requires specialized testing equipment and expertise.

- Weather-dependent testing conditions.

- Difficult to fully test until the envelope is substantially complete.

- Remediation can be extremely invasive and costly if not caught early.

Examples of Successful Implementation:

Globally recognised construction firms like Gilbane Building Company, PCL Construction, and Boston Properties demonstrate the effectiveness of robust envelope quality programs on large-scale projects. These companies employ rigorous testing and commissioning processes, including mock-up testing for complex assemblies, demonstrating the importance of this process for projects of all sizes.

Tips for Homeowners:

- Conduct progressive testing throughout the envelope installation.

- Use full-scale mock-ups for high-risk assemblies, particularly for bespoke designs.

- Document all flashing and transition details with photographs before concealment.

- Perform testing under various weather conditions when possible to ensure resilience.

- Implement third-party envelope consultants for complex systems for an unbiased expert opinion.

This proactive approach can save you significant money and headaches in the long run. Learn more about Building Envelope Quality Control

This item deserves a prominent place on any construction quality control checklist because it addresses a critical aspect of building performance and longevity. By prioritizing building envelope quality control, you are investing in a more durable, energy-efficient, and comfortable home. For affluent homeowners in Australia, this ensures their investment not only looks stunning but also performs flawlessly for years to come.

Popularized by organizations like the Building Enclosure Council (BEC), ASTM E2813 Standard for Building Enclosure Commissioning, the National Institute of Building Sciences (NIBS), and RDH Building Science, building envelope quality control is a crucial aspect of modern construction best practices.

5. MEP Systems Verification

MEP Systems Verification is a critical component of any construction quality control checklist, especially for complex projects like custom luxury residences, modern extensions, bespoke renovations, and smart homes. It involves the rigorous inspection and testing of mechanical, electrical, and plumbing systems to ensure they are installed correctly, function as designed, and comply with Australian Standards and local building codes. This process covers everything from verifying equipment installation and distribution systems to conducting performance testing of integrated building systems, guaranteeing optimal operation and long-term reliability. Ignoring this crucial step can lead to costly rework, energy inefficiency, and compromised occupant comfort.

How it Works:

MEP Systems Verification is a multi-stage process, typically involving the following:

- Pre-installation coordination review: This involves reviewing shop drawings and coordination between different trades (mechanical, electrical, and plumbing) to identify and resolve potential clashes or conflicts before installation begins. This is particularly important in renovations and extensions where existing systems need to integrate seamlessly with new installations.

- Rough-in inspections: Inspections are carried out after the initial installation of MEP systems (pipes, wiring, ductwork) but before walls and ceilings are closed. This allows for easy access for inspection and rectification of any issues.

- Pressure testing: Piping systems are pressure tested to identify leaks and ensure their integrity. This is crucial for both water supply and drainage systems.

- Electrical testing and circuit verification: Electrical circuits are tested to ensure they are wired correctly and function safely, meeting Australian electrical safety standards.

- Functional performance testing of equipment: HVAC units, ventilation systems, and other equipment are tested to ensure they operate as per manufacturer specifications and design requirements.

- Commissioning and integrated systems testing: This final stage involves testing all systems together to ensure they function as an integrated whole, delivering the desired performance and efficiency. For technology-oriented homeowners investing in smart homes, this stage is vital to ensure seamless integration of all automated systems.

Examples of Successful Implementation:

While the examples listed (Jacobs Engineering Group, Syska Hennessy, and WSP) represent large-scale projects, the principles of meticulous MEP systems verification apply equally to high-end residential projects. Imagine a perfectly balanced HVAC system in your new second-floor extension, ensuring consistent temperature throughout the year, or a flawlessly integrated smart home system managing lighting, security, and entertainment seamlessly – this is the outcome of robust MEP systems verification.

Benefits for Australian Homeowners:

- Ensures building systems operate as designed: This guarantees the performance and longevity of your investment, whether it’s a ground-floor extension or a complete home renovation.

- Prevents costly access issues for future repairs: Identifying and rectifying problems during construction avoids the expense and disruption of accessing concealed systems later.

- Reduces energy consumption through proper system balancing: Optimised systems translate to lower energy bills and a smaller carbon footprint.

- Improves occupant comfort and system reliability: This is paramount for Australian homeowners, ensuring a comfortable and healthy living environment.

- Validates compliance with Australian Standards and regulations: This protects homeowners from potential legal and insurance issues.

Pros and Cons:

- Pros: Improved system performance, reduced energy costs, enhanced occupant comfort, increased reliability, regulatory compliance.

- Cons: Requires coordination across trades, potential for construction delays, need for specialized testing equipment and personnel.

Actionable Tips:

- Develop system-specific testing plans: Tailor the testing protocols to the specific requirements of your project, whether it's a custom home build or a renovation.

- Create detailed inspection checklists: Ensure comprehensive coverage of all aspects of the MEP systems.

- Document all concealed installations before closure: This is crucial for future maintenance and troubleshooting.

- Implement progressive commissioning throughout construction: This allows for early identification and rectification of issues.

- Use data logging for extended performance verification: This provides valuable data for ongoing system optimisation and maintenance.

Why MEP Systems Verification Deserves its Place on the Checklist:

For discerning Australian homeowners investing in high-value properties, MEP Systems Verification is non-negotiable. It's the assurance that your investment will deliver the promised comfort, efficiency, and reliability. By meticulously verifying every aspect of your MEP systems, you are safeguarding your investment and ensuring a truly luxurious and functional living environment. This proactive approach minimizes future headaches and ensures long-term satisfaction with your dream home.

6. Safety and Code Compliance Verification

Safety and Code Compliance Verification is a crucial component of any construction quality control checklist, especially for complex projects like custom luxury residences, modern extensions, bespoke renovations, and smart, energy-efficient homes. This systematic process ensures that all construction elements adhere to Australian building codes, safety standards, and regulatory requirements. It covers everything from fire protection systems and accessibility features to structural safety elements, occupational safety provisions, and environmental compliance measures. Neglecting this aspect can lead to costly rework, project delays, and potential legal liabilities down the line. This is why it deserves a prominent place in your construction quality control checklist.

This process involves meticulously evaluating each aspect of the construction against specific code requirements. This is achieved through the use of code-specific inspection checklists, coordination with the relevant Authority Having Jurisdiction (AHJ), and often, third-party verification for specialized systems like fire suppression or complex structural engineering. Thorough documentation of compliance is essential for obtaining permit approvals and ensuring a smooth transition to occupancy. This includes documenting life safety systems testing and certification.

For affluent homeowners investing in high-end projects, this process provides invaluable peace of mind. Knowing that your second-floor extension, ground-floor expansion, or whole-house renovation meets stringent safety and code requirements assures you of a safe, functional, and legally compliant structure. Learn more about Safety and Code Compliance Verification

Features of a robust Safety and Code Compliance Verification process include:

- Code-Specific Inspection Checklists: These checklists provide a structured approach to verifying compliance with specific building codes.

- Coordination with AHJ: Direct communication with the local authorities ensures clear understanding and adherence to their interpretations of the codes.

- Third-Party Verification: Independent experts can provide unbiased assessments of specialized systems, providing an extra layer of assurance.

- Documentation of Compliance: Meticulous record-keeping facilitates permit approvals and demonstrates due diligence.

- Life Safety Systems Testing and Certification: This verifies that crucial safety systems like fire alarms and sprinklers are functioning correctly.

Pros:

- Reduces Legal and Regulatory Liability: Compliance minimizes the risk of fines, legal action, and insurance issues.

- Ensures Occupant Safety and Accessibility: Adherence to codes protects the well-being of everyone who uses the building.

- Facilitates Smooth Approvals and Occupancy Permits: Proper documentation streamlines the approval process.

- Establishes Comprehensive Safety Documentation: This provides a valuable record for future maintenance and inspections.

- Provides Verification of Insurance Requirements: Compliance often satisfies insurance prerequisites for coverage.

Cons:

- Code Interpretations May Vary: Different jurisdictions and inspectors may have varying interpretations of the same code, leading to potential inconsistencies.

- Changes in Codes During Construction: Updates to building codes during a project can necessitate costly redesigns.

- Coordination with Multiple Regulatory Agencies: Complex projects may involve multiple agencies, adding complexity to the coordination process.

- Documentation Requirements Can Be Extensive: Maintaining comprehensive records can be time-consuming.

Examples of Successful Implementation:

Large construction firms like Clark Construction, Webcor Builders, and Hensel Phelps have implemented sophisticated safety and code compliance programs for major projects, demonstrating the effectiveness of these systems. These systems track compliance, manage inspections, and ensure adherence to stringent regulatory requirements.

Tips for Effective Safety and Code Compliance Verification:

- Schedule Pre-Construction Meetings with Code Officials: Early engagement clarifies expectations and avoids potential misunderstandings.

- Maintain a Current Code Analysis Throughout the Project: Stay informed about any code updates or changes that may impact the project.

- Document All Inspections and Approvals in a Central Repository: This ensures easy access to all relevant documentation.

- Implement Interim Reviews Before Official Inspections: Internal reviews can identify and address potential issues before formal inspections.

- Create Detailed Tracking for All Permit Conditions and Requirements: This helps ensure that all conditions are met before occupancy.

By prioritizing Safety and Code Compliance Verification, homeowners embarking on construction projects can ensure the long-term safety, legality, and value of their investments. This proactive approach minimizes risks and paves the way for a successful and stress-free construction experience.

7. Documentation and Information Management

Effective construction quality control hinges on meticulous documentation. This crucial element of any successful project, and a key component of any construction quality control checklist, encompasses the comprehensive system for collecting, organizing, and maintaining all quality-related records. This includes everything from test results and inspections to submittals, compliance documentation, and photographic/video evidence, creating a verifiable record of quality control activities throughout the entire construction process. This meticulous approach provides the basis for project acceptance, future reference, and offers valuable insights for continuous improvement.

For discerning homeowners in Australia undertaking high-end projects such as custom luxury residences, modern extensions, bespoke renovations, or technology-driven smart homes, robust documentation is paramount. Whether you’re adding a second-story extension or expanding on the ground floor, having a clear and accessible record of every decision, material used, and inspection conducted is essential for a smooth and successful outcome.

This system operates by establishing standardized procedures and utilizing various tools, including:

- Digital document management systems: Software platforms designed specifically for construction projects streamline the process, facilitating efficient collaboration and real-time updates.

- Real-time quality data collection and reporting: This enables immediate identification and rectification of potential issues, minimizing delays and cost overruns.

- Standardized forms and templates: These ensure consistency in data collection and reporting across all project phases.

- Photographic and video documentation: Visual records provide undeniable proof of workmanship and material quality, particularly useful for complex details or hidden elements.

- Secure archiving and retrieval systems: These protect valuable project data and ensure easy access for future reference, warranty claims, or building maintenance.

- Cloud-based accessibility for stakeholders: This fosters transparent communication and collaboration amongst all parties involved, including homeowners, architects, builders, and inspectors.

The benefits of meticulous documentation are numerous:

- Creates legal protection and evidence of compliance: Detailed records demonstrate adherence to building codes and regulations, protecting homeowners in case of disputes.

- Facilitates transparent communication with owners and regulators: Open access to information builds trust and ensures everyone is informed about the project's progress and quality.

- Provides data for continuous improvement: Analyzing project data can identify areas for optimization in future projects.

- Supports warranty management and building maintenance: Access to historical records simplifies warranty claims and facilitates ongoing maintenance.

- Enables efficient closeout and turnover process: Complete documentation streamlines the final handover, ensuring a smooth transition for the homeowner.

However, there are some challenges to consider:

- Requires significant administrative resources: Implementing and maintaining the system necessitates dedicated personnel and time.

- System adoption can be challenging across diverse project teams: Getting everyone on board and using the system consistently requires training and ongoing support.

- Potential information overload without proper organization: Effective organization and indexing are critical for easy retrieval and analysis.

- Technology dependencies and compatibility issues: Choosing the right software and ensuring compatibility across different platforms can be complex.

Examples of successful implementation include Procore's quality management on the Jeddah Tower, Autodesk Construction Cloud's documentation system for Hudson Yards, and Bentley Systems' ProjectWise for Crossrail. These large-scale projects highlight the value of comprehensive documentation in managing complex construction endeavors.

To effectively implement a documentation and information management system for your project, consider the following tips:

- Establish documentation standards at project inception: Define clear guidelines and procedures for document creation, storage, and retrieval.

- Use consistent file naming and organization conventions: This simplifies searching and prevents duplication.

- Implement regular quality document audits: Periodic reviews ensure accuracy and completeness.

- Train field personnel on documentation requirements: Ensure everyone involved understands their responsibilities.

- Create dashboard reporting for quality metrics and trends: Visual representations of key data provide valuable insights and facilitate proactive decision-making.

Learn more about Documentation and Information Management

Popular platforms used in the AU region include Procore Technologies, Autodesk Construction Cloud, PlanGrid, and Bentley Systems. By prioritizing documentation and information management within your construction quality control checklist, you are investing in the long-term success and value of your project, a crucial step for affluent homeowners investing in significant property improvements.

7-Point Construction QC Checklist Comparison

Quality Control Item | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Materials Testing and Inspection | Medium - Coordination with labs needed | Moderate - Specialized equipment & labs | Ensures material quality, reduces rework | Projects with critical material standards | Prevents substandard materials, documented proof |

Dimensional Quality Control | High - Skilled personnel & advanced tech | High - Surveying instruments, BIM tools | Accurate spatial installation, reduces clashes | Complex structures needing precision alignment | Prevents cumulative errors, improves aesthetics |

Workmanship Standards Verification | Medium - Requires trade expertise | Moderate - Inspectors and documentation | Consistent craft quality, reduces callbacks | Large, multi-trade projects | Establishes quality expectations, visual records |

Building Envelope Quality Control | High - Specialized testing & weather dependency | High - Testing equipment & expertise | Weathertight, energy-efficient building envelope | Enclosures needing durability and performance | Prevents water damage, improves energy efficiency |

MEP Systems Verification | High - Coordination across trades | High - Specialized test equipment/training | Proper system functioning, energy and safety compliance | Systems-heavy buildings (medical, commercial) | Validates system operations and safety |

Safety and Code Compliance Verification | Medium - Coordination with regulators | Moderate - Compliance docs & inspections | Legal adherence, occupant safety | All construction requiring permits | Reduces liability, facilitates approvals |

Documentation and Information Management | Medium - Requires admin systems | Moderate - Digital systems and training | Transparent records, supports warranty & turnover | All projects demanding traceability | Legal protection, data for continuous improvement |

Building with Confidence: The Power of Proactive Quality Control

Implementing a robust construction quality control checklist is paramount to the success of any building project, especially for discerning homeowners in Australia pursuing luxury custom builds, modern extensions, bespoke renovations, or smart, energy-efficient homes. From meticulous materials testing and inspection to stringent MEP systems verification and comprehensive documentation, each item on the construction quality control checklist contributes significantly to mitigating potential problems and ensuring the longevity, value, and overall quality of your investment. Whether you're adding a second-story extension or expanding your ground floor, prioritizing these seven key areas—materials, dimensions, workmanship, building envelope, MEP systems, safety/code compliance, and documentation—will empower you to achieve a truly exceptional final product. Mastering these concepts translates directly into a smoother construction process, fewer costly rectifications down the line, and ultimately, a home that reflects your vision and stands the test of time. By proactively addressing quality control, you transform the building journey from a potential source of stress into a rewarding experience culminating in a home you’ll cherish for years to come.

For a seamless building experience that prioritizes quality at every stage, partner with Envy Abode. We meticulously implement a comprehensive construction quality control checklist to ensure your dream home becomes a stunning reality. Visit Envy Abode to discover how we bring exceptional quality and design to life.